The company’s integrated approach—combining R&D capabilities from multiple production bases with rigorous quality assurance—makes us the ideal partner for businesses seeking to enhance their printing capabilities with efficient, cost-effective technology.

1. What types of printing equipment are most suitable for starting a textile printing business?

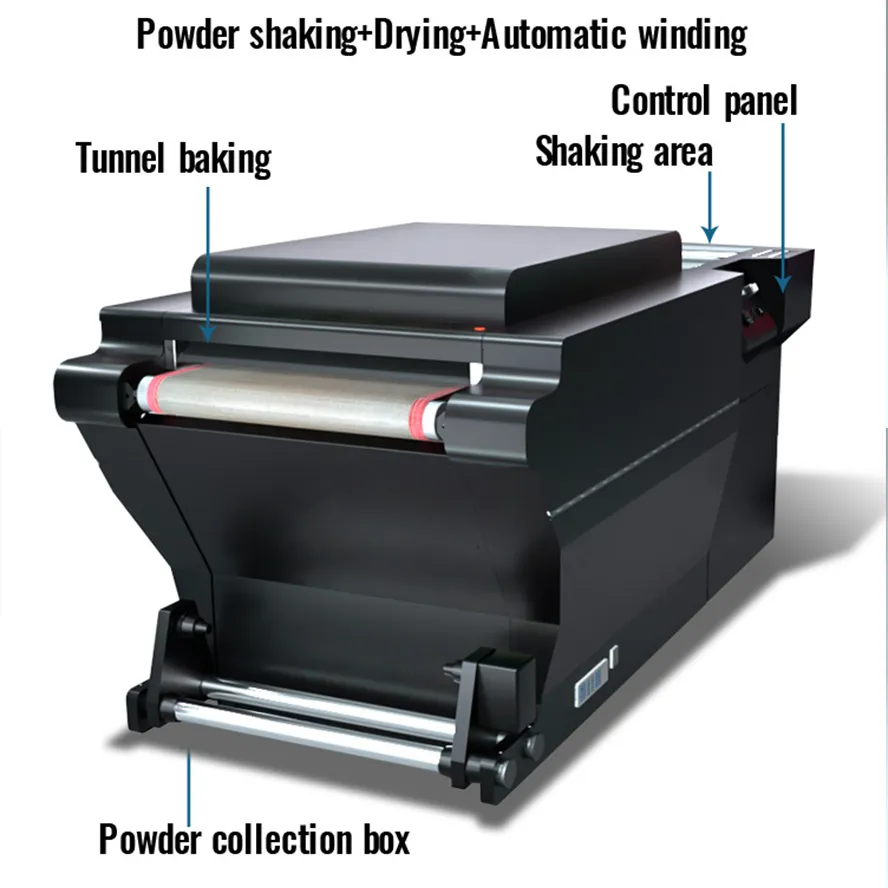

For entrepreneurs entering textile printing, we recommend starting with versatile and user-friendly equipment like our DTF (Direct-to-Film) printers and heat press machines. These systems offer excellent print quality, relatively low startup costs, and the ability to work with various fabrics without pretreatment. Our A3 size DTF printer with powder shaker functionality is particularly popular among startups as it handles small to medium production runs efficiently while maintaining professional results. The learning curve is manageable, and the equipment can scale with your business growth. As both manufacturer and supplier, we provide comprehensive training materials and technical support to ensure new customers can quickly master the technology and begin production with confidence.

2. How does your equipment ensure color consistency across different advertising materials?

Our printing systems incorporate advanced color management technology and precision Epson print heads to maintain exceptional color consistency across various substrates. The integrated RIP software allows for precise color profiling and calibration, ensuring that colors remain vibrant and accurate whether printing on textiles, banners, or rigid materials. For advertising applications where brand colors must be perfectly matched, our equipment supports Pantone color libraries and custom profile creation. The automated maintenance systems prevent nozzle clogging and ink starvation, which are common causes of color variation. As a manufacturer, we conduct rigorous quality tests on each unit to guarantee consistent output performance, making our machines ideal for advertising agencies that require reliable color reproduction across different media types.

3. What maintenance procedures are required to keep textile printing equipment operational?

Regular maintenance is essential for optimal performance and longevity of textile printing equipment. Daily procedures should include nozzle check patterns, print head cleaning (if needed), and ensuring ink levels are adequate. Weekly maintenance involves thorough cleaning of the printer interior, inspection of mechanical components, and lubrication of moving parts as specified in our manuals. For DTF printers, particular attention should be paid to the powder shaker system and film feeding mechanisms to prevent clogging. As your supplier, we provide detailed maintenance schedules and video tutorials for all our machines. Our technical support team is available 24/7 to guide users through any complex procedures, and we stock all necessary spare parts to minimize downtime through our global distribution network.

4. Can your printing equipment handle both soft textiles and rigid advertising materials?

Yes, many of our advanced systems are designed to handle both soft textiles and rigid advertising materials with minimal adjustments. Our UV DTF printers, for example, can print onto specialized films that are then transferred to virtually any surface including textiles, metal, glass, plastic, and wood. This versatility makes them ideal for advertising agencies that need to produce everything from apparel and fabrics to signage and promotional items. The printing process remains largely the same regardless of material, though transfer parameters may vary. As a manufacturer focused on flexible solutions, we offer customizable configurations that can be optimized for specific material types, allowing our clients to expand their service offerings without investing in multiple specialized machines.

5. What technical support and training do you provide for international wholesale clients?

We offer comprehensive technical support and training programs for our international wholesale clients. This includes detailed installation guides, operation manuals, and video tutorials available in multiple languages. Our support team provides 24/7 remote assistance through video calls and team viewer sessions to troubleshoot issues in real-time. For larger wholesale partners, we offer on-site training sessions at your facility (subject to agreement terms) to ensure your team fully understands equipment operation and maintenance. We maintain an extensive inventory of spare parts distributed globally to minimize downtime. Additionally, as a manufacturer with OEM capabilities, we provide specialized training for white-label products, marketing support, and technical documentation tailored to your branding requirements, ensuring you can effectively support your own customers.