- Download free sample catalogs

- Consult our experts about printer information

- Get the latest promotional offers

- Get Customized Printing Solutions

- One-Stop Procurement Solutions

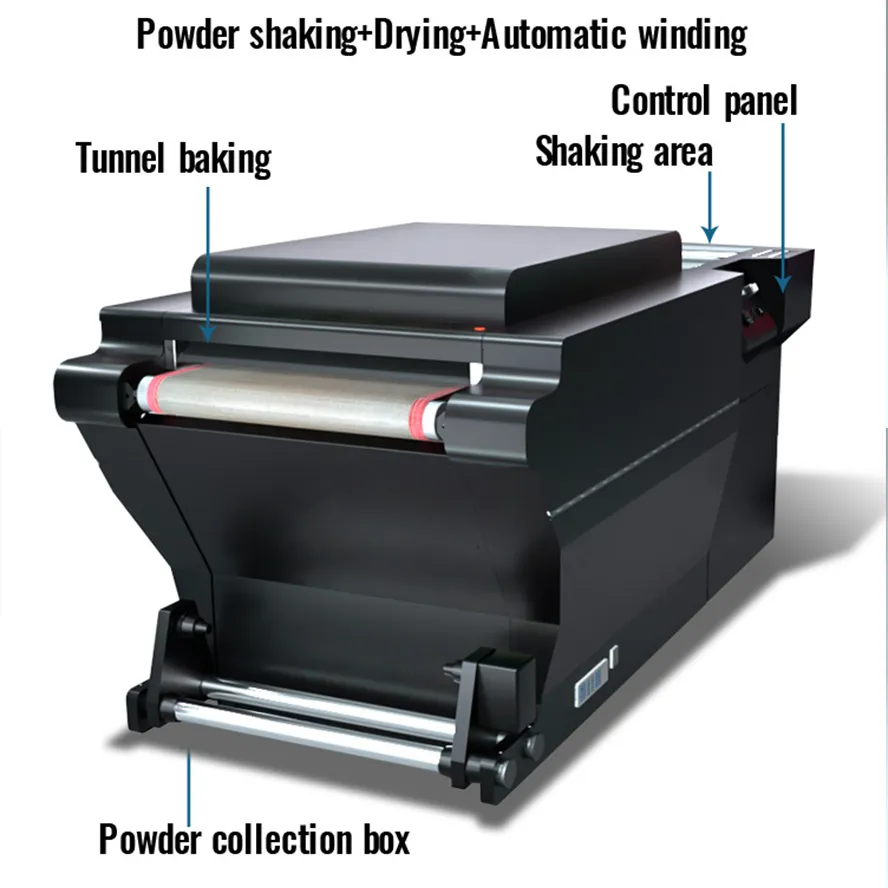

Powder Shakers Machines

Professional Powder Shakers Machines Manufacturer

Henan Zunsun Machinery is a leading manufacturer and global supplier of high-efficiency Powder Shakers Machines, leveraging over 10 years of specialized experience in DTF (Direct-to-Film) printing equipment. Our CE-certified powder shakers feature precision vibration systems, adjustable powder flow controls, and stainless steel construction for consistent, uniform powder distribution. We offer fully customizable solutions including automatic and semi-automatic models with various hopper capacities to match different production volumes. As a trusted wholesaler partner, we provide comprehensive technical support and OEM services, ensuring optimal performance for DTF printing operations worldwide.

Get the print information you want for free.

Applications

Knowledge

Struggling with Uneven Powder Distribution and Material Waste?

Are inconsistent powder coverage and excessive material usage increasing your production costs and affecting print quality? These common issues typically stem from inferior vibration mechanisms, poor powder flow control, and inadequate screening systems in low-quality machines. The consequences include wasted expensive powder materials, rejected transfers due to uneven coverage, and reduced production efficiency from frequent adjustments. Henan Zunsun addresses these challenges with our precision-engineered Powder Shakers Machines featuring advanced vibration technology, micrometer-adjusted powder flow controls, and anti-clogging screening systems that ensure perfect, consistent powder distribution across all DTF transfers while minimizing material consumption.

Powder shakers machines are specialized devices used in DTF printing to evenly distribute hot-melt powder onto printed designs. They ensure proper powder adhesion before heat pressing, creating durable, flexible transfers. Key features include adjustable vibration intensity, powder flow control, and screening systems for consistent results.

Global Applications and Proven Reliability

Our Powder Shakers Machines serve DTF printing operations worldwide, from small custom print shops to large-scale garment manufacturing facilities. With installations in over 50 countries, we have demonstrated capabilities in high-volume production environments requiring consistent, reliable powder application. Our manufacturing facilities in Zhengzhou, Shandong, and Guangdong maintain stringent quality control and significant production capacity to meet both standard and customizable orders. Each machine undergoes rigorous testing for vibration consistency, powder distribution accuracy, and operational durability, ensuring they meet the demanding requirements of international wholesaler networks and printing professionals who prioritize quality and efficiency in their DTF production processes.

What is a powder shaker machine used for in DTF printing?

Powder shaker machines are essential components in Direct-to-Film (DTF) printing processes, specifically designed for applying hot-melt powder onto printed designs before heat pressing. The machine evenly distributes powder across the entire printed surface, ensuring proper adhesion and preventing powder buildup in specific areas. As a professional manufacturer, our machines feature precision vibration systems that maintain consistent powder distribution regardless of design complexity or size. This process is crucial for creating durable, flexible transfers that can withstand washing and wearing when applied to garments. The adjustable settings allow operators to control powder density based on specific material requirements, making our machines indispensable for professional DTF operations serving wholesaler markets and retail customers.

How to choose the right powder shaker machine for your business?

Selecting the appropriate powder shaker requires considering several key factors. Production volume determines whether you need a manual, semi-automatic, or fully automatic model – our customizable options accommodate all throughput levels. The powder type and particle size influence the required screening system specifications, which we optimize for different powder varieties. Machine construction quality is vital; our stainless steel builds ensure durability and prevent corrosion from powder residues. As a experienced supplier, we recommend evaluating vibration consistency, adjustability range, and ease of cleaning when choosing equipment. Additional features like digital controls, automatic powder recycling systems, and compatibility with existing DTF lines should also be considered to ensure seamless integration into your production workflow.

What maintenance do powder shaker machines require?

Regular maintenance is crucial for optimal powder shaker performance. Daily cleaning of the screening mesh prevents clogging and ensures consistent powder distribution. Weekly inspection of vibration motors and mechanical components maintains operational reliability. Monthly calibration checks ensure powder flow settings remain accurate. As a professional manufacturer, our machines are designed with quick-disassembly features for easy cleaning and maintenance. We recommend using only recommended powder types to prevent machine damage and ensure best results. Proper storage in low-humidity environments prevents powder condensation and machine corrosion. Our machines include detailed maintenance guides and video tutorials, and we offer customizable service packages through our global wholesaler network to keep your equipment running at peak performance with minimal downtime.

Can powder shaker machines handle different powder types?

Yes, high-quality powder shakers can accommodate various powder types, but require specific adjustments for optimal performance. Standard DTF powders with 100-150 mesh size work best with standard screening systems, while finer powders may require specialized meshes to prevent leakage. As a leading supplier, our machines feature adjustable vibration intensity and powder flow controls that can be calibrated for different powder characteristics including density, particle size, and flow properties. We offer customizable screening systems and hopper configurations for specialized applications involving unique powder formulations. The machine’s stainless steel construction ensures compatibility with all common powder types without corrosion or contamination issues, making our equipment versatile enough to handle evolving powder technologies in the rapidly developing DTF industry.

How do powder shaker machines improve DTF printing efficiency?

Powder shakers significantly enhance DTF production efficiency through multiple mechanisms. They reduce powder consumption by up to 30% through precise distribution control, directly lowering material costs. Automated systems increase production speed by 50% compared to manual powder application, allowing faster order fulfillment. Consistent powder application reduces rejection rates due to uneven coverage, improving overall product quality. As a professional manufacturer, our machines feature quick-change settings that minimize adjustment time between different jobs, while integrated dust collection systems maintain clean working environments and reduce powder waste. These efficiency improvements make powder shakers essential investments for DTF operations serving wholesaler markets where competitive pricing and consistent quality are critical for business success.

Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.